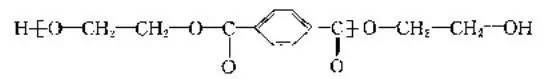

Polyester feem ntau yog hais txog lub siab molecular compound tau los ntawm polycondensation ntawm dibasic acid thiab dibasic cawv, thiab nws cov kab txuas txuas txuas nrog ester bonds. Muaj ntau ntau hom polyester fibers, xws li polyethylene terephthalate (PET) fiber, polybutylene terephthalate (PBT) fiber, polypropylene terephthalate (PPT) fiber, thiab lwm yam ntawm lawv, cov fibers nrog polyethylene terephthalate cov ntsiab lus ntawm ntau tshaj 85% yog lub ntsiab. cov, thiab qhov hnyav molecular feem ntau tswj ntawm 18000 thiab 25000. Lub ntsiab molecular qauv yog raws li nram no:

1. Polyester (PET) fiber ntau

Kev tshawb fawb ntawm polyester tau pib hauv xyoo 1930s. Nws tau tsim los ntawm cov neeg Askiv xws li whinfield thiab Dickson. Nyob rau hauv 1949, nws yog industrialized nyob rau hauv teb chaws Aas Kiv thiab nyob rau hauv 1953 nyob rau hauv lub tebchaws United States. Nws yog ib yam khoom ntawm ntau yam ntawm hluavtaws fibers uas tsim lig, tab sis tsim sai heev.

Qhov hnyav molecular ntawm polyester yog 18000 ~ 25000, thiab cov degree ntawm polymerization yog 100 ~ 140. Macromolecules muaj cov qauv tshuaj symmetrical. Nyob rau hauv cov xwm txheej tsim nyog, macromolecules yog ib qho yooj yim los tsim cov muaju thiab cov qauv fiber ntau yog compact. Polyester macromolecules muaj benzene rings, uas yog ib qho nyuaj macromolecules. Nyob rau tib lub sijhawm, lawv kuj muaj aliphatic hydrocarbon chains, ua rau cov molecules hloov tau. Tsis muaj lwm pawg polar nyob rau hauv macromolecule tsuas yog ob pawg cawv uas tau txiav tawm hydroxyl. Nrog cov ntsiab lus ester siab, hydrolysis thiab thermal tawg yuav tshwm sim ntawm qhov kub thiab txias. Polyester yog yaj spun. Nws hla ntu yog puag ncig, nws txoj kab ntev yog iav pas nrig, thiab nws qhov ceev yog 1.38 ~ 1.40g / cm3.

Hauv Suav teb, cov fiber ntau nrog polyethylene terephthalate cov ntsiab lus ntau dua 85% yog hu ua polyester, feem ntau hu ua "Dacron". Muaj ntau lub npe khoom txawv teb chaws, xws li "Dacron" hauv Tebchaws Meskas, "tetoron" hauv Nyiv, "terlenka" hauv tebchaws United Kingdom, thiab "lavsan" hauv qub Soviet Union.

2. Cationic dyeable polyester (CDP) fiber ntau

Hloov kho polyester (CDP) tuaj yeem dyed nrog cationic dyes los ntawm kev qhia cov pab pawg acidic uas tuaj yeem khi cationic dyes rau hauv PET molecular chains. CDP yog thawj zaug tsim los ntawm American DuPont tuam txhab. Thaum kawg ntawm lub xyoo pua 20th, nws cov txiaj ntsig tau suav txog 1/6 ntawm tag nrho cov zis ntawm PET fiber ntau. Nws cov ntau hom muaj xws li dacron t64, dacron T65, thiab lwm yam CDP tsis tsuas yog muaj kev ua haujlwm zoo dyeing, tab sis kuj tuaj yeem dyeing hauv tib da dej nrog ntuj fibers xws li ntaub plaub, uas yooj yim rau kev yooj yim ntawm dyeing txheej txheem ntawm blended fabrics. Yog tias nws tau muab sib xyaw thiab sib cuam tshuam nrog cov polyester zoo tib yam, nws tuaj yeem tsim tib lub da dej sib txawv xim, uas ua rau cov xim zoo nkauj ntawm cov ntaub. Yog li ntawd, CDP tau dhau los ua ntau yam kev hloov pauv polyester. CDP feem ntau yog npaj los ntawm kev ntxiv peb lossis plaub monomer, xws li sodium dimethyl isophthalate sulfonate (SIPM), rau cov tsiaj macromolecular saw los ntawm copolymerization thiab graft copolymerization. Raws li cov pab pawg tsis zoo sulfonic acid ntxiv rau CDP molecular saw, thaum dyeing, cov hlau ions ntawm sulfonic acid pawg yuav pauv nrog cov cations hauv cov xim, yog li cov dye ions yuav raug kho ntawm CDP macromolecular saw. Cov ntsev uas tsim los ntawm dyeing yuav raug tshem tawm tas li nyob rau hauv cov tshuaj aqueous, thiab cov tshuaj tiv thaiv yuav txuas ntxiv mus. Thaum kawg, cov nyhuv dyeing yuav ua tiav.

Cov txheej txheem tsim khoom ntawm CDP zoo ib yam li cov tsiaj, uas tuaj yeem muab faib ua ntu zus thiab sib cuam tshuam. Vim muaj qhov sib txawv ntawm cov khoom siv raw, CDP tuaj yeem muab faib ua DMT txoj kev thiab PTA txoj kev. CDP rhuav tshem cov qauv qub ntawm cov fiber ntau vim qhov sib ntxiv ntawm cov pab pawg tshiab hauv cov saw hlau macromolecular, uas txo qhov melting point, iav hloov kub thiab crystallinity ntawm fiber. Hauv thaj av amorphous, qhov chaw nruab nrab ntawm qhov chaw nce, uas yog qhov zoo rau cov xim molecules nkag mus rau hauv cov fiber ntau. Lub zog ntawm CDP yog qis dua li ntawm cov polyester zoo tib yam, tab sis cov cuab yeej tiv thaiv pilling ntawm cov ntaub yog txhim kho, thiab tus kov yog mos thiab plump. Nws tuaj yeem siv los ua cov ntaub plaub zoo li cov khoom lag luam. Kev dyeing ntawm CDP feem ntau tseem xav tau qhov kub thiab txias (120 ~ 140 ℃) thiab kub siab los yog nyob rau hauv cov xwm txheej ntawm kev ntxiv cov cab kuj, thiaj li muaj cov khoom dyeing zoo dua. Yog li ntawd, thaum xaiv dyes, nws yuav tsum tau muab sau tseg tias cov xaiv dyes yuav tsum muaj zoo thermal stability.

3. Chav tsev kub thiab atmospheric siab dyeable polyester (ECDP) fiber ntau

Lub dyeable polyester ECDP ntawm qhov kub thiab txias tuaj yeem npaj tau los ntawm kev ntxiv me me ntawm plaub monomer hauv cov txheej txheem ntawm cov tsiaj zoo tib yam polymerization. Qhov no feem ntau yog vim hais tias cov polyethylene glycol saj zawg zog saw ntu tau nkag mus rau hauv cov tsiaj macromolecular saw, uas ua rau cov qauv molecular ntawm fiber ntau xoob thiab thaj tsam amorphous loj, uas yog qhov zoo dua rau kev nkag ntawm cationic dyes rau hauv fiber ntau thiab kev sib xyaw ua ke. nrog ntau sulfonic acid pawg. Yog li ntawd, nws tuaj yeem dyed nyob rau hauv ib txwm muaj siab boiling dyeing tej yam kev mob. ECDP fiber ntau muaj softer tes xav thiab hnav zoo dua li CDP thiab PET fiber ntau. Txawm li cas los xij, vim tias lub zog qis ntawm qhov thib plaub monomer polyethylene glycol ntu, thermal stability ntawm ECDP fiber yog txo, thiab lub zog poob ntawm ECDP fiber ntau tshaj 30% ntawm qhov kub ntawm ironing ntawm 180 ℃. Yog li, cov ntaub ua los ntawm ECDP fiber ntau yuav tsum tau them nyiaj tshwj xeeb hauv kev kho tom qab, ntxuav thiab ironing.

4. PTT fiber ntau

PTT fiber yog cov ntawv luv ntawm polypropylene terephthalate fiber. Qee cov neeg txawv teb chaws hu PTT lub fiber ntau ntawm lub xyoo pua 21st, thiab nws lub npe lag luam yog "Corterra".

PTT, tsiaj thiab PBT yog cov tsev neeg polyester, thiab lawv cov khoom zoo sib xws. PTT fiber ntau muaj cov yam ntxwv ntawm polyester thiab nylon. Nws yog yooj yim los ntxuav thiab qhuav li polyester, muaj zoo elasticity rov qab thiab crease kuj, thiab muaj kuab paug tsis kam, lub teeb kuj thiab tes xav. Nws muaj dyeing kev ua tau zoo dua li polyester, thiab tuaj yeem dyed nyob rau hauv ib txwm siab. Nyob rau tib lub sijhawm, kev nkag mus ntawm cov dyeing rau PTT fiber ntau yog siab dua li cov tsiaj, thiab dyeing yog uniform thiab xim ceev ceev yog qhov zoo. Piv nrog rau nylon, PTT fiber ntau kuj muaj kev hnav zoo dua thiab tensile rov qab, thiab muaj cov yam ntxwv ntawm elasticity loj thiab zoo fluffy, yog li nws yog qhov tsim nyog rau cov ntaub pua plag thiab lwm yam ntaub ntawv.

5. PBT fiber ntau

PBT fiber yog cov ntawv luv ntawm polybutylene terephthalate fiber. PBT fiber ntau yog ua los ntawm dimethyl terephthalate (DMT) lossis terephthalic acid (TPA), cov khoom siv tseem ceeb ntawm polyester, thiab 1,4 - butanediol. PBT fibers tau npaj los ntawm yaj spinning ntawm DMT thiab 1,4 - butanediol ntawm qhov kub thiab txias, siv cov organic titanium los yog tin compounds thiab tetrabutyl titanate ua catalysts. Lub polymerization, spinning, post-processing technology thiab cov khoom siv ntawm PBT fiber yog yeej ib yam li cov polyester.

PBT fiber ntau muaj cov yam ntxwv zoo ib yam li polyester fiber, xws li lub zog zoo, yooj yim ntxuav thiab ziab sai, ruaj khov loj, zoo zoo tuav, thiab lwm yam, qhov tseem ceeb tshaj plaws yog qhov hloov pauv ntawm nws cov macromolecular saw ntev, yog li nws tawg thiab stretches, muaj zoo elasticity, muaj kev hloov me ntsis hauv elasticity tom qab cua sov, thiab zoo li mos. Lwm qhov zoo ntawm PBT fiber ntau yog tias nws cov dyeability zoo dua li ntawm polyester. PBT ntaub tuaj yeem dyed nrog disperse dyes nyob rau hauv cov xwm txheej ntawm boiling dyeing ntawm atmospheric siab. Tsis tas li ntawd, PBT fiber ntau muaj kev tiv thaiv kev laus, tshuaj lom neeg thiab kub ua haujlwm. PBT fiber ntau yog siv dav hauv engineering plastics, cov khoom siv hauv tsev thiab cov khoom siv tshuab.

6. cwj mem fiber

Pen fiber yog cov ntawv luv ntawm polyethylene naphthalate fiber. Zoo li polyester, cwj mem fiber ntau yog cov khoom siv semi crystalline thermoplastic polyester, uas tau pib qhia los ntawm KASA tuam txhab ntawm Tebchaws Meskas. Nws cov txheej txheem ntau lawm yog los ntawm transesterification ntawm dimethyl 2,6 - naphthalene dicarboxylate (NDC) thiab ethylene glycol (eg), thiab tom qab ntawd polycondensation; Lwm txoj kev yog ncaj qha esterification ntawm 2,6 - naphthalene dicarboxylic acid (NDCA) thiab ethylene glycol (eg), thiab tom qab ntawd polycondensation. Lub thermal stability ntawm tus cwj mem tuaj yeem txhim kho los ntawm kev ntxiv me me ntawm cov tebchaw uas muaj cov organic amines thiab organic phosphorus.

Cov txheej txheem spinning ntawm cwj mem fiber ntau zoo ib yam li polyester. Cov txheej txheem ntws yog: nti kom qhuav → kev kub ceev spinning → sau. Raws li cov iav hloov pauv kub ntawm cov cwj mem fiber ntau siab dua li ntawm polyester fiber, cov txheej txheem tsim qauv yuav tsum tau hloov raws li. Kev siv ntau dhau yuav tsum tau txais kev pom zoo thiab qhov ntsuas kub yuav tsum tau nce kom tsis txhob cuam tshuam cov fiber ntau vim qhov qeeb molecular orientation ceev. Piv nrog cov pa polyester, cov cwj mem fiber ntau muaj cov khoom siv zoo dua qub thiab thermal, xws li lub zog siab, siab modulus, zoo tensile kuj thiab siab rigidity; Cov cua kub zoo, ruaj khov loj, tsis yooj yim rau deform, nplaim hluav taws zoo; Cov tshuaj tiv thaiv zoo thiab hydrolysis tsis kam; UV kuj thiab aging kuj.

7. ntub thiab qhuav polyester filament

Los ntawm kev hloov pauv cov duab ntawm cov ntoo fiber ntau, qhov sib txawv ntawm cov fibers ib leeg yog nce, qhov tshwj xeeb ntawm qhov chaw yog nce, thiab cov nyhuv capillary zoo heev txhim kho nws cov dej noo conductivity, thiaj li ua rau cov ntub thiab qhuav polyester filament. Cov ntaub fiber ntau muaj cov dej noo zoo heev thiab kev ua haujlwm ya raws diffusion. Nws yog txuam nrog paj rwb fibers thiab lwm yam fibers nrog zoo noo noo nqus. Nrog rau lub koom haum tsim nyog, cov nyhuv zoo dua. Cov khaub ncaws qhuav, txias thiab xis nyob. Nws yog tsim rau knitted sportswear, woven shirts, lub caij ntuj sov khaub ncaws fabrics, polyester stockings, thiab lwm yam.

8. High dehumidification plaub channel polyester fiber

Du Pont tau tsim TEFRA - channel polyester fiber nrog lub peev xwm zoo heev. Nws yog cov dej noo siab ua fiber ntau ua los ntawm hydrophobic hluavtaws fiber, uas tuaj yeem tawm hws los ntawm cov tawv nqaij tawm hws mus rau cov ntaub nto rau evaporative txias. Cov txiaj ntsig tau pom tias qhov kev tshem tawm noo noo feem pua ntawm cov paj rwb fiber ntau yog 52% thiab ntawm plaub channel polyester fiber yog 95% tom qab 30min. Cov fiber ntau no tshwj xeeb tshaj yog siv rau hauv cov khaub ncaws ua kis las thiab cov tub rog hnav khaub ncaws thermal underwear, uas tuaj yeem ua kom cov tawv nqaij qhuav thiab xis nyob, thiab muaj kev txuag hluav taws xob zoo thiab cov ntaub ntawv pov thawj txias.

9. Polyester ntxeem tau hollow seem fiber ntau "wellkey"

Wellkey lub hom phiaj kev loj hlob yog coj cov hws ua kua ua cov khoom kom ua tiav hws nqus thiab ziab sai. Wellkey yog polyester hollow fiber. Los ntawm qhov chaw ntawm fiber ntau, muaj ntau qhov pores nkag mus rau hauv qhov hollow. Cov dej ua kua tuaj yeem nkag mus rau hauv qhov khoob ntawm qhov chaw fiber ntau. Cov qauv fiber ntau no tsom rau qhov siab tshaj plaws ntawm dej nqus thiab cov ntsiab lus noo noo. Nyob rau hauv cov txheej txheem spinning, ib tug tshwj xeeb pore forming tus neeg sawv cev tau muab sib xyaw thiab yaj los ua cov qauv fiber ntau. Cov fiber ntau muaj qhov nqus tau zoo heev thiab ziab sai, thiab feem ntau yog siv los ua cov ntaub ntawm petticoats, tights, sportswear, tsho, khaub ncaws, tsho loj thiab lwm yam khaub ncaws. Tsis tas li ntawd, vim nws qhov zoo ntawm kev nqus dej thiab ziab sai thiab cov nqi ziab qis, nws kuj muaj cov ntawv thov dav dav hauv cov chaw tsis hnav thiab kev kho mob thiab kev noj qab haus huv.

10. Peb seem crimped hollow polyester fiber

Peb-dimensional crimp fibers thaum ntxov tau tsim los ntawm kev siv ob lub polymers nrog cov khoom sib txawv los ntawm kev sib xyaw spinning tshuab thiab cov txheej txheem txias txias. Tom qab kos duab, nws tsim ntuj crimp vim qhov sib txawv ntawm shrinkage. Cov txheej txheem kev npaj tam sim no tau ua tiav zoo, uas yog, nws tau txais qhov tshwj xeeb patented thev naus laus zis ntawm eccentric spinneret qhov tsim, ua ke nrog asymmetric forming txias system thiab sib txuas ntxiv cov duab kos thiab shaping txheej txheem, Cov npaj fiber ntau muaj siab curl degree, ntuj thiab mus tas li curl. thiab zoo warmth tuav. Tam sim no, cov tsim ntau yam muaj xws li plaub lub qhov, xya lub qhov los yog txawm cuaj qhov peb-dimensional crimped hollow fibers. Peb seem crimped hollow fiber ntau yog siv dav hauv kev sau thiab thermal fiber ntau.

Kev sau cov ntaub ntawv: dyeing thiab tiav Encyclopedia

Los ntawm: official account fabric course

Post lub sij hawm: Jun-21-2022