What is Taly fiber?

Taly fiber is a kind of regenerated cellulose fiber with excellent performance produced by American Taly company. It not only has the excellent moisture absorption and wearing comfort of traditional cellulose fiber, but also has a unique natural self-cleaning function and its own characteristics of non stick oil. The fabrics processed with it are soft and more shiny than silk fabrics. These products have the characteristics of hygroscopic, breathable, stable size, bright color and good drapability. Taly fiber blended with various fibers has a wide variety of products. It is not only cool to wear, but also does not need any detergent and bleach after wearing. It can wash off the oil stains on it only in clean water, which can be decomposed by itself after use. Will not pollute the environment. Compared with other fibers, taiy fiber has high functionality, good air permeability, unique resilience and greater strength. Therefore, it is widely used in the textile and garment industry.

Properties and characteristics of Taly fiber

(1) Taly fiber is a new type of wood pulp fiber. It uses 100% pure white pine wood pulp and a production process similar to Tencel fiber to produce a regenerated cellulose fiber with excellent properties.

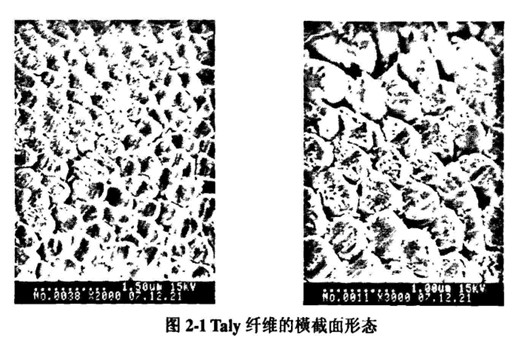

(2) The cross section of Taly fiber is round or approximately oval with sawtooth shape. Its surface and inner layer have different structural characteristics. The surface structure is relatively compact and the surface is smooth, while the inner layer structure is relatively loose and has more voids.

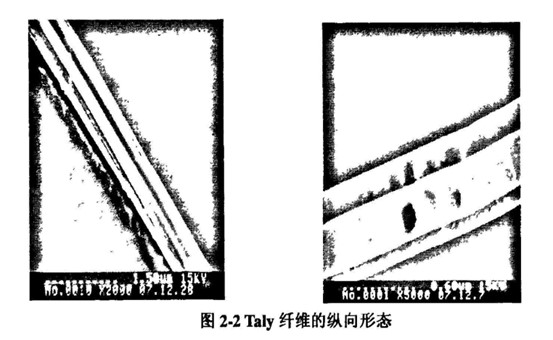

(3) There are grooves of different depths and small protrusions on the longitudinal surface of Taly fiber. This structure can make a large number of voids in the internal structure of yarn and fabric, which is conducive to improving the moisture absorption of the product and the air permeability of the fabric.

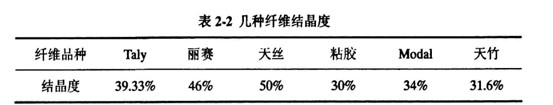

(4) Taly fiber has the same crystal structure as Tencel fiber, Richcel fiber and modal fiber, and belongs to monoclinic crystal system.

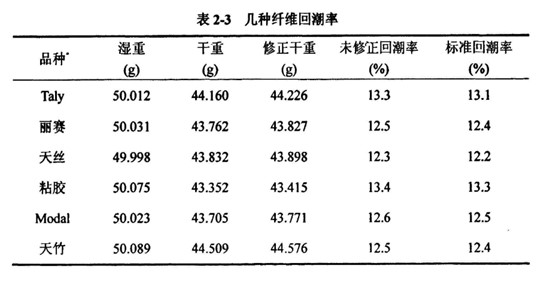

(5) Taly fiber is a kind of regenerated cellulose fiber. The macromolecule contains a large number of hydrophilic groups. It has high moisture regain, good moisture absorption, fast moisture absorption rate, strong capillary effect and good air permeability. The surface of the fiber can be kept dry to ensure the comfort of clothing.

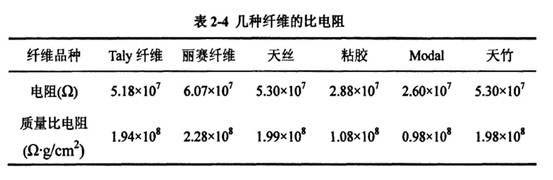

(6) The mass specific resistance of Taly fiber is equal to that of Tencel fiber and higher than that of modal fiber; Lower than Richcel fiber. The surface of Taly fiber has a certain friction coefficient, and there is a good holding force between fibers. It is not easy to generate static electricity during spinning, and has good spinnability.

(7) Taly fiber has good dyeing performance. The dyes used for viscose fiber can also be used for Taly fiber. It has bright dyeing and good color fastness. High dye uptake, not easy to fade, good stability, complete chromatography, can be dyed and processed into various colors.

(8) Taly fiber has better characteristics than viscose fiber, and has its unique advantages, such as soft hand feeling, soft luster and silk feeling. The processed silk like products have strong silk quality, soft color, plump, fine and clean, elegant and flowing, smooth and soft, and elegant style.

(9) Taly fiber has good heat resistance and thermal stability, alkali resistance and acid resistance, and outstanding sun resistance and ultraviolet resistance. In addition, it also has good mold resistance, moth resistance and antifouling properties.

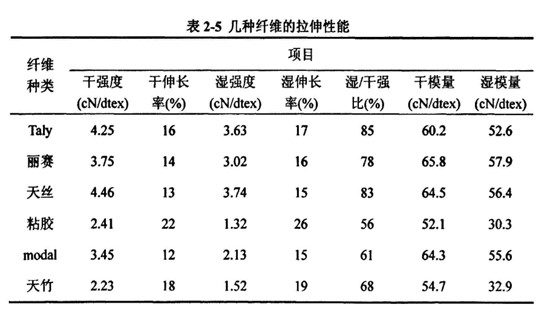

(10) Taly fiber has large wet modulus and initial modulus, high crystallinity, high degree of polymerization, hook strength and nodule strength. The fiber is full of elasticity, small deformation, large elastic recovery rate, good elasticity and deformation resistance. The processed products are elastic, plump and crisp, with excellent wrinkle resistance, good shape retention and dimensional stability after washing.

(11) the wood used in the processing of Taly fiber is specially cultivated. The raw material comes from the wood pulp of the trees in the artificial planting area. It is pure natural lignin. The processed products are degradable and will not release harmful gases during combustion, which will not pollute the environment. Since no chemical raw materials are used in the processing of Taly fiber, it will not damage the natural environment and has environmental protection performance.

Application and product development of Taly fiber

The excellent performance of Taly fiber can be used to process Knitted products, such as thermal underwear, lower shirts and other products, as well as woven fabrics, such as high-end shirt fabrics and women’s high-end clothing.

1. Woven products

Taly fiber can be blended with Tencel, modal fiber, aloe fiber, bamboo charcoal polyester fiber, bamboo charcoal viscose fiber, corn fiber, pearl fiber, etc. the developed product has a novel and unique style, and feels smooth. It is blended with flax, Apocynum, ramie, wool, cashmere, etc. the developed product has good moisture absorption and permeability, luxurious and elegant appearance, and good wearability.

2. Imitation silk products

The interweaving of Taly fiber with silk, polyester filament, viscose filament, polypropylene filament, nylon filament, pupa protein viscose filament, soybean protein filament, pearl fiber filament and aloe viscose fiber filament can develop various silk like products with good performance

3. High grade underwear

The Taly fiber can be used to process women’s underwear, corsets, women’s casual wear, etc. these products have soft luster, clear patterns, soft touch, good elasticity, moisture absorption and ventilation, and have the effects of bacteriostasis, odor prevention and sterilization. The products have good comfort and skin affinity.

——Select from China Fabric Sample Warehouse

Post time: Jun-14-2022