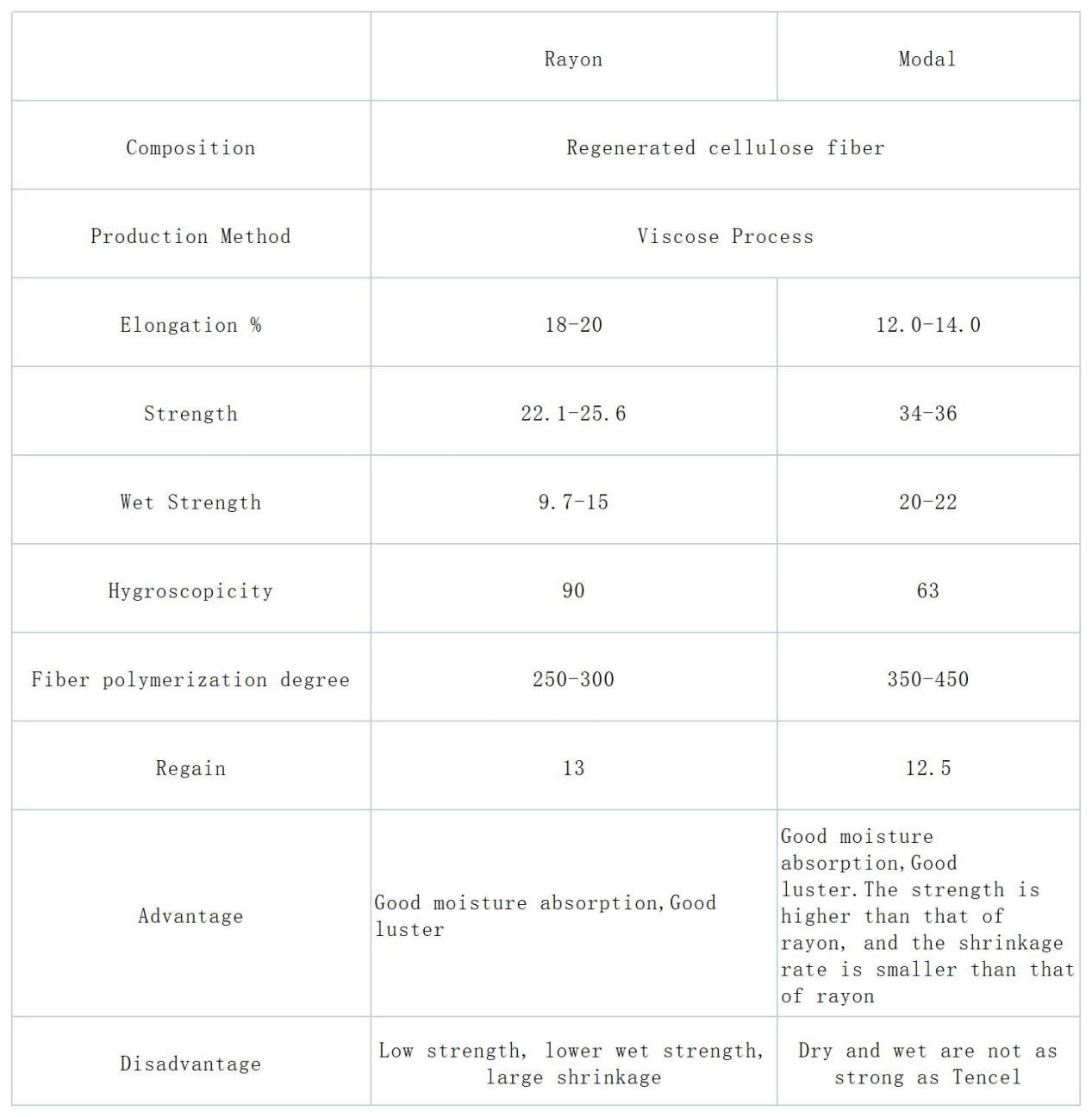

Modal and rayon are both recycled fibers, but the raw material of Modal is wood pulp, while the raw material of rayon is natural fiber. From a certain point of view, these two fibers are green fibers. In terms of hand feel and style, they are very similar, but their prices are far from each other.

Modal

Modal fiber is a newly developed fabric in recent years, which is called Modal for short. It is a modern fiber that combines the luxury texture of natural fibers with the practicality of synthetic fibers. It has the softness of cotton, the luster of silk, and the smoothness of hemp. Moreover, its water absorption and air permeability are better than cotton, and it has a high dye uptake. The fabric color is bright and full. Modal fiber can be blended and interwoven with a variety of fibers, such as cotton, hemp, silk, etc., to improve the quality of these fabrics, so that the fabric can remain soft and smooth, give play to the characteristics of their respective fibers, and achieve better wearing effect.

Rayon

Rayon is the common name of viscose fiber, which is called rayon for short. Viscose fiber is extracted from cellulose raw materials such as wood and plant ligusticum α- Cellulose, or man-made fiber made from cotton linter, which is processed into spinning stock solution and then wet spun. To sum up, rayon is a kind of regenerated fiber.

Differences between Modal and Rayon:

Modal is a cellulose regenerated fiber of high wet modulus viscose fiber developed by Lenzing, Austria. The raw material of this fiber is beech wood from Europe. It is first made into wood pulp, and then processed into fiber through special spinning process. The raw materials of this product are all natural materials, which are harmless to human body, can be naturally decomposed, and is harmless to the environment. Modal fiber is a kind of cellulose fiber, which is made from shrubbery produced in Europe and made of wood slurry through special spinning process. It is a pure natural fiber, which belongs to the same category as cotton.

Modal products have good softness and excellent moisture absorption, but their fabrics have poor stiffness. Now it is mostly used in the production of underwear. Modal knitted fabrics are mainly used to make underwear. But Modal has silver white luster, excellent dyeability and bright color after dyeing, which is enough to make it used as a coat. Because of this, Modal has increasingly become a material for coats and decorative cloth. In order to improve the poor stiffness of pure Modal products, Modal can be blended with other fibers to achieve good results. JM/C (50/50) can remedy this shortcoming. The blended fabric woven with this yarn makes the cotton fiber more flexible and improves the appearance of the fabric. Modal can also show its weaveability in the weaving process of woven fabrics, and can also be interwoven with other fiber yarns to weave various fabrics. Modal products have broad prospects for development in modern clothing.

Rayon is viscose fiber, a major variety of man-made fibers. Alkali cellulose is formed from natural cellulose through alkalization, and then reacts with carbon disulfide to form cellulose xanthate. The viscous solution obtained by dissolving it in dilute alkali solution is called viscose. Viscose fiber is formed after wet spinning and a series of treatment procedures. Its basic composition is that the cross section of cellulose (C6H10O5) no ordinary viscose fiber is zigzag skin core structure, straight in the longitudinal direction and grooved in the transverse direction. The fiber rich coreless structure has a circular cross-section.

Viscose fiber has good moisture absorption, and the moisture regain is about 13% under general atmospheric conditions. After moisture absorption, it expands significantly, and the diameter increases by 50%, so the fabric feels hard and has a large shrinkage rate after being put into the water.

The breaking strength of ordinary viscose fiber is lower than that of cotton, about 1.6~2.7 cN/dtex; Elongation at break is 16%~22% higher than that of cotton; The wet strength decreases much, about 50% of the dry strength, and the wet elongation increases by about 50%. Its modulus is lower than that of cotton, and it is easy to deform under small load, while its elastic recovery performance is poor, so the fabric is easy to elongate and has poor dimensional stability. The strength of rich fiber, especially the wet strength, is higher than that of ordinary viscose, the elongation at break is smaller, and the dimensional stability is good. The abrasion resistance of ordinary viscose is poor, while that of rich fiber is improved.

The chemical composition of viscose fiber is similar to that of cotton, so it is more alkali resistant than acid resistant, but its alkali and acid resistance are worse than that of cotton. Rich fiber has good alkali resistance and acid resistance. Similarly, the dyeing property of viscose fiber is similar to that of cotton, with complete dyeing chromatography and good dyeing property. In addition, the thermal properties of viscose fiber are similar to that of cotton, with a density of 1.50~1.52g/cm3 close to that of cotton.

The ordinary viscose fiber has good hygroscopicity, is easy to dye, is not easy to generate static electricity, and has good spinnability. Short fibers can be pure spun or blended with other textile fibers. The fabric is soft, smooth, breathable, comfortable to wear, bright color and good color fastness after dyeing. It is suitable for making underwear, outerwear and various decorative articles. Filament fabrics are light and thin, and can be used for making quilt covers and decorative fabrics in addition to clothes. The disadvantages of this type of viscose fiber are poor fastness, low wet modulus, high shrinkage, easy deformation, poor elasticity and wear resistance.

Summary:

As both rayon and Modal are recycled fibers, electrostatic reaction transactions occur. Serious static electricity plus friction will produce open fire. In autumn and winter, fabric electrostatic reaction transactions also cause fabric fuzzing and pilling. Now more and more merchants add antistatic finishing in the later stage of the fiber. This can not only improve the wearing comfort of the fabric, but also prevent the fabric from fuzzing and pilling, and improve the feel and beauty of the fabric. For example, ZJ-Z09H non-ionic antistatic agent can effectively improve the moisture absorption and conductivity of the fabric, as well as the anti fouling and dust-proof properties, and can also improve the anti pilling of the fabric by more than 0.5 level.

Post time: Nov-22-2022